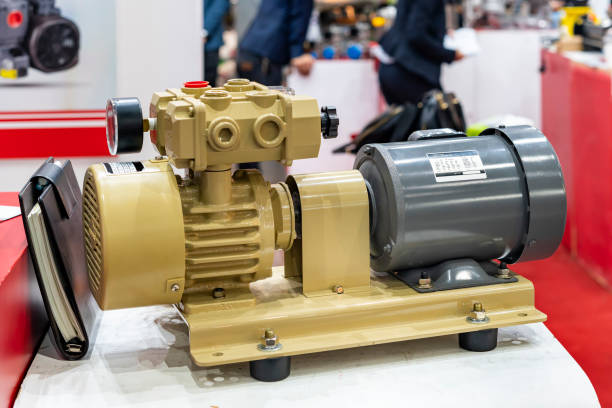

Vacuum era performs a essential position in modern-day enterprise, from chemical processing to electricity technology. Among the numerous styles of vacuum structures available, the liquid ring vacuum pump stands out for its simplicity, sturdiness, and flexibility. These pumps are designed to handle moist and corrosive gases, making them best for processes that involve condensation, vapor healing, and gasoline compression beneath tough running situations.

An skilled industrial product manufacturer will regularly propose liquid ring structures for applications that require reliable vacuum technology in difficult environments. Their capability to feature with minimal upkeep and their tolerance for manner fluids make them a favored desire in many sectors.

How Liquid Ring Vacuum Pumps Operate

Basic Operating Principle

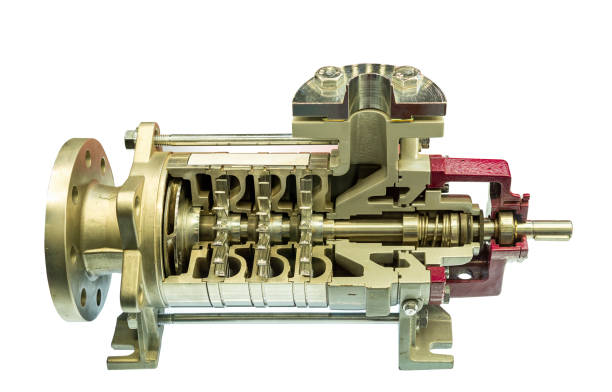

A liquid ring vacuum pump makes use of a rotating impeller set up eccentrically within a cylindrical casing. The pump chamber is partly filled with a sealing liquid—normally water, despite the fact that other drinks can be used for particular applications. As the impeller rotates, the liquid is thrown outward by way of centrifugal force to shape a ring around the casing’s indoors wall. This liquid ring creates a chain of sealed compression chambers between the impeller blades.

As the quantity of those chambers will increase on the suction facet of the pump, gasoline is drawn in via the inlet. When the chambers reach the release side, their volume decreases, compressing the fuel and forcing it out thru the exhaust port. The sealing liquid absorbs warmth generated during compression, making sure smooth and cool operation.

Handling of Condensable Vapors

Unlike other vacuum technologies, liquid ring pumps are well-desirable for handling vapors that could condense in the course of compression. The sealing liquid absorbs and contains these vapors, stopping damage to the pump and decreasing emissions.

Types of Liquid Ring Vacuum Pump Configurations

Single-Stage Liquid Ring Pumps

Single-stage pumps complete the compression manner in a single rotation cycle. They are green for low to moderate vacuum tiers and are usually used in general commercial programs. Their honest design and price-effectiveness cause them to suitable for utility-level vacuum requirements.

Two-Stage Liquid Ring Pumps

Two-stage pumps compress fuel across two impellers in collection. This layout complements performance and permits for deeper vacuum levels in comparison to single-level fashions. They are extensively utilized in demanding methods consisting of solvent restoration, vacuum distillation, and degassing in excessive-vacuum applications.

Closed-Loop Systems

Closed-loop structures recirculate the sealing liquid thru a heat exchanger before re-entering the pump. This configuration conserves water or different sealing fluids and keeps a steady working temperature, making it perfect for programs requiring liquid conservation or precise thermal manipulate.

Once-Through Systems

In once-thru designs, sealing liquid enters the pump, plays its function, and is then discharged. These systems are easier however eat more liquid, which may not be suited in water-scarce or environmentally sensitive places. They are commonly used in which fluid costs are low and infection risks are minimum.

Partial Recovery Systems

Partial restoration systems strike a stability among the preceding two by way of convalescing and reusing a portion of the sealing liquid at the same time as discharging the rest. These structures provide reasonable conservation at the same time as simplifying the device format.

Key Benefits of Using Liquid Ring Vacuum Pumps

Capability to Handle Wet Gases

Liquid ring pumps can technique saturated gases and vapors with out performance loss. This makes them ideal for chemical, petrochemical, and meals processing industries where moisture-laden gases are not unusual.

Minimal Wear and Long Service Life

Because the pump additives are lubricated and cooled by means of the sealing liquid, there is minimal friction and wear. This consequences in lengthy-lasting operation with decrease maintenance frequency and price.

Intrinsically Safe Design

Liquid ring pumps are non-sparking and feature low inner temperatures, making them inherently safe to be used in explosive or flammable environments. They are usually hired in vapor recovery gadgets and gasoline-coping with systems in oil refineries.

Reduced Noise and Vibration

The operation of a liquid ring vacuum pump is surprisingly quiet and vibration-free compared to other mechanical vacuum structures. This is positive in environments where noise reduction and operational stability are essential.

Broad Material Compatibility

Depending on the software, liquid ring pumps can be constructed using numerous substances consisting of forged iron, stainless-steel, and bronze. This flexibility lets in them to deal with corrosive or reactive gases when paired with well matched sealing beverages.

Industrial Applications of Liquid Ring Systems

Chemical and Pharmaceutical Industries

In chemical manufacturing, liquid ring pumps are used to evacuate reactors, recover solvents, and manage off-gassing from numerous processes. Their ability to deal with corrosive vapors and particulates makes them nicely-proper for pharmaceutical manufacturing and laboratory vacuum systems.

Food and Beverage Processing

Liquid ring pumps help in tactics like bottling, packaging, and freeze-drying via preserving controlled atmospheric conditions. Their hygienic operation and tolerance for vapors support excessive standards of protection and product first-rate.

Pulp and Paper Manufacturing

In the paper industry, vacuum structures help in water removal at some point of sheet formation and urgent. Liquid ring vacuum pumps are preferred for their capacity to work in moist and fibrous environments with out clogging or overheating.

Power Generation and Environmental Control

These pumps are utilized in steam condenser evacuation, fuel extraction, and air removal from cooling systems in thermal strength flora. They also play a position in vapor healing and fuel scrubbing systems used to manipulate emissions in diverse commercial operations.

Important Considerations for System Selection

Required Vacuum Level

The desired vacuum intensity notably impacts pump selection. For widespread vacuum requirements, unmarried-degree models may additionally suffice, at the same time as extra disturbing programs gain from -level or closed-loop designs that offer deeper vacuum tiers.

Availability of Sealing Liquid

Water is the maximum common sealing fluid, however in water-touchy environments, systems need to be designed to minimize intake. Closed-loop or partial restoration structures are ideal in such situations.

Temperature Control

Maintaining the sealing liquid at an finest temperature is crucial for steady pump performance. Heat exchangers are frequently included into recirculation systems to manipulate thermal buildup all through prolonged operation.

Space and Installation Constraints

Liquid ring pumps are to be had in various configurations to healthy exclusive footprints and mounting orientations. Some fashions are skid-mounted with all components incorporated for simplified set up and mobility.

Maintenance and Operational Guidelines

Routine Monitoring

Monitoring parameters which includes temperature, vacuum level, and liquid flow rate guarantees reliable operation. Unusual noise or decreased performance may additionally imply cavitation, seal put on, or obstruction in fluid paths.

Sealing Liquid Quality

The condition of the sealing liquid immediately affects pump performance. Contaminants or adjustments in fluid residences can cause corrosion or loss of vacuum performance. Regular fluid analysis and substitute are encouraged.

Periodic Cleaning

Over time, scale and deposits might also form inside the pump and piping. Scheduled flushing or chemical cleansing helps hold internal cleanliness, specifically in systems uncovered to minerals or natural residues.

Environmental and Operational Efficiency

Water Conservation

Closed-loop and partial restoration systems extensively reduce water consumption, reducing operational expenses and environmental effect. This is more and more vital as industries move towards sustainable practices.

Energy Optimization

While liquid ring pumps are energy-extensive, device design can limit electricity use by incorporating variable frequency drives, automatic controls, and optimized piping layouts to reduce losses and friction.

Emissions Control

By condensing vapors into the sealing fluid, liquid ring pumps assist reduce the quantity of airborne emissions released into the atmosphere. This supports compliance with environmental guidelines and place of job protection standards.

Conclusion

The liquid ring vacuum pump stays a critical issue in a wide range of industrial structures because of its adaptability, strong construction, and tolerance for hard running conditions. From handling condensable vapors to processing corrosive gases, its versatility is unequalled in vacuum generation. Whether used in unmarried-level setups for widespread packages or in complex closed-loop structures for excessive-demand tactics, liquid ring pumps deliver reliable and green overall performance.

Selecting the right configuration and running with an experienced industrial product producer ensures that the gadget meets operational, environmental, and fee-performance goals. With thoughtful layout and regular preservation, liquid ring vacuum systems continue to be a reliable spine in endless industrial applications.

Frequently Asked Questions (FAQ)

What is the principle advantage of the usage of a liquid ring vacuum pump?

Its potential to address moist, corrosive, or particulate-encumbered gases makes it ideal for hard industrial environments in which other vacuum technology might also fail.

How does a two-stage liquid ring pump fluctuate from a single-degree model?

A -level pump gives deeper vacuum ranges via compressing fuel in levels, enhancing performance and decreasing discharge temperatures for demanding applications.

Can the sealing liquid be something other than water?

Yes, relying on chemical compatibility and thermal requirements, different fluids like glycol, oil, or specialised solvents can be used as sealing beverages.

How regularly should a liquid ring vacuum pump be serviced?

Basic inspections have to arise weekly or month-to-month, whilst fluid alternative and inner cleansing can be scheduled quarterly or yearly primarily based on system usage and environment.

Are liquid ring pumps electricity-green?

While not the maximum electricity-green option, their sturdiness and capacity to address difficult gases often outweigh better strength intake. System design and fluid management can similarly optimize efficiency.